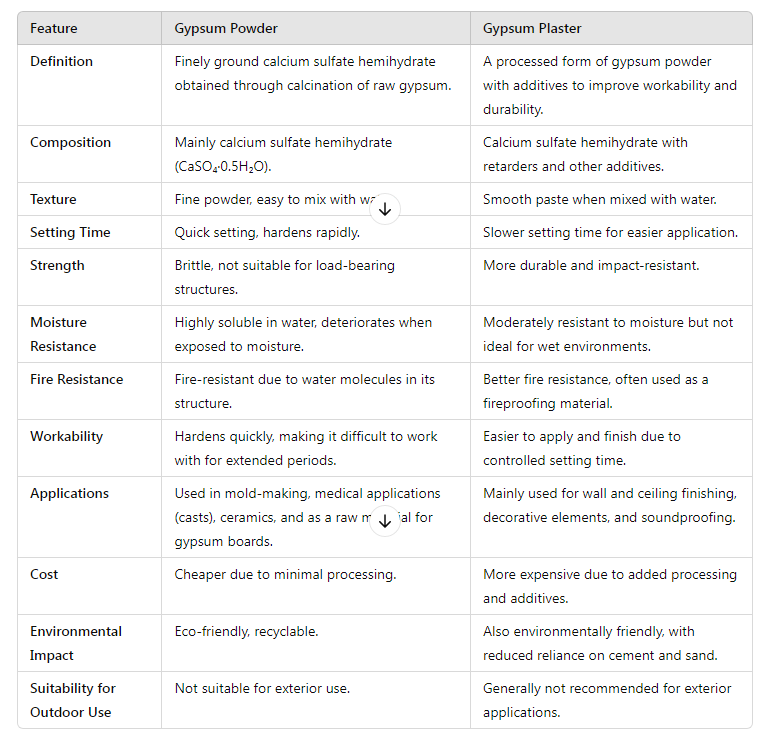

Gypsum is a widely used mineral in construction and industrial applications due to its versatility and ease of use. It is found in different forms, with gypsum plaster and gypsum powder being two of the most common derivatives. While they may appear similar at first glance, there are distinct differences between these materials in terms of composition, applications, benefits, and limitations. This article provides an in-depth comparison between gypsum plaster and gypsum powder to help consumers and professionals understand their uses and suitability for various applications.

What is Gypsum?

Gypsum is a naturally occurring mineral composed of calcium sulfate dihydrate (CaSO₄·2H₂O). It is extracted from sedimentary rock formations and is widely used in construction, agriculture, and industrial manufacturing. The unique properties of gypsum, such as its fire resistance, ease of application, and durability, make it a preferred choice for building materials. The processing of gypsum results in two primary products: gypsum powder and gypsum plaster, each with its distinct properties and applications.

Gypsum has been used since ancient times in various civilizations, including Egyptian and Roman architecture. The ability of gypsum to be easily shaped and set into solid structures made it a staple in construction and artistic designs. In modern applications, gypsum continues to be widely used in homes, offices, and large-scale industrial projects. Understanding the differences between gypsum powder and gypsum plaster can help builders, architects, and homeowners choose the right material for their specific needs.

Gypsum Powder: Composition and Characteristics

Gypsum powder is obtained by heating raw gypsum rock at high temperatures to remove water content, a process known as calcination. This results in calcium sulfate hemihydrate (CaSO₄·0.5H₂O), commonly referred to as plaster of Paris (POP). The characteristics of gypsum powder include:

- Fine Texture: Gypsum powder is finely ground, making it easy to mix with water and spread evenly across surfaces.

- Quick Setting: When mixed with water, gypsum powder forms a paste that sets rapidly, allowing for fast application.

- Versatile Applications: It is used in construction, medicine, ceramics, and mold-making, making it a multipurpose material.

- Soluble in Water: Although it hardens when mixed with water, it can be dissolved over time when exposed to continuous moisture.

Advantages of Gypsum Powder

Gypsum powder has several benefits, making it a valuable material across industries. Some of these advantages include:

Lightweight: Compared to cement and other building materials, gypsum powder is lightweight, making it easy to transport and apply.

Smooth Surface: It provides a high-quality finish, which is ideal for moldings, statues, and decorative elements.

Eco-Friendly: Gypsum is a naturally occurring, recyclable material, reducing environmental waste.

Limitations of Gypsum Powder

Despite its advantages, gypsum powder also has some limitations:

- Moisture Sensitivity: Gypsum powder is not suitable for outdoor use or in areas with high humidity as it absorbs water and loses strength.

- Brittle Nature: It can be fragile and prone to breaking under heavy pressure.

- Limited Load-Bearing Capacity: It is not suitable for structural applications requiring high compressive strength.

Gypsum Plaster: Composition and Characteristics

Gypsum plaster is made from gypsum powder but undergoes additional processing to improve its properties for construction applications. When gypsum powder is mixed with water, it forms a paste that hardens as it dries. Gypsum plaster includes additives that enhance its workability, durability, and water resistance. The characteristics of gypsum plaster include:

- Smooth Finish: Gypsum plaster provides a smooth surface for walls and ceilings, eliminating the need for additional finishing layers.

- Durability: It is more resistant to wear and impact than raw gypsum powder, making it a long-lasting material.

- Fire Resistance: The presence of water molecules in gypsum gives it excellent fire-retardant properties, making buildings safer.

- Crack Resistance: Gypsum plaster is less prone to cracking compared to traditional cement plaster, ensuring better longevity.

Advantages of Gypsum Plaster

Gypsum plaster offers several advantages, including:

Faster Construction: It sets quickly, reducing overall construction time compared to traditional cement plaster.

Better Insulation: It has thermal and acoustic insulating properties, making it an energy-efficient choice for homes and offices.

Low Shrinkage: Unlike cement plaster, which can shrink and crack over time, gypsum plaster maintains its form and strength.

Non-Toxic: Gypsum plaster is a non-toxic material, making it safe for use in homes, hospitals, and schools.

Limitations of Gypsum Plaster

While gypsum plaster has many benefits, it also has certain drawbacks:

- Higher Cost: Compared to traditional cement plaster, gypsum plaster can be more expensive.

- Water Sensitivity: Although more resistant than gypsum powder, gypsum plaster is still vulnerable to prolonged exposure to moisture.

- Not Suitable for Exterior Use: It is mainly used for interior applications and is not recommended for outdoor surfaces.

Production Process: How They Are Made

Gypsum Powder Production:

- Extraction: Raw gypsum rock is extracted from quarries or mines.

- Crushing and Grinding: The extracted material is crushed into smaller pieces and then ground into a fine powder.

- Calcination: The powdered gypsum is heated at 150-180°C to remove moisture, turning it into calcium sulfate hemihydrate (plaster of Paris).

- Packaging: The processed gypsum powder is packaged for distribution and use.

Gypsum Plaster Production:

- Mixing with Additives: Gypsum powder is mixed with retarders and other additives to modify setting time and enhance durability.

- Application Processing: The modified gypsum is prepared for use as a finishing material for walls and ceilings.

- Setting and Drying: When applied to surfaces, the gypsum plaster sets as it dries, forming a solid, smooth layer.

Applications of Gypsum Powder and Gypsum Plaster

Uses of Gypsum Powder:

- Construction: Used as a base material for producing gypsum boards, panels, and plasters.

- Medical Field: Applied in making orthopedic casts and surgical molds.

- Ceramics Industry: Used in mold-making for pottery and sculpture.

- Agriculture: Helps in soil conditioning and as a fertilizer to improve soil structure.

Uses of Gypsum Plaster:

- Wall and Ceiling Finishing: Applied directly onto masonry, bricks, or concrete for smooth finishes.

- Decorative Purposes: Used to create ornamental moldings and ceiling designs.

- Fireproofing Material: Provides fire-resistant coatings in buildings.

- Acoustic Insulation: Used in soundproofing systems to improve indoor acoustics.

Conclusion

Gypsum powder and gypsum plaster serve different purposes despite being derived from the same mineral. Gypsum powder is a raw material used in various industries, while gypsum plaster is a refined product used primarily in construction. Understanding their differences helps in selecting the right material for specific applications, ensuring efficiency, durability, and cost-effectiveness. Whether for structural finishing, medical applications, or artistic creations, gypsum remains an essential and versatile material in modern industries. The decision between gypsum plaster and gypsum powder ultimately depends on the requirements of the project, budget considerations, and environmental factors.